PVC Shrink Film For Printing Label

Product parameter

| ITEM | UNIT | TYPICAL VALUES |

| Width | mm | 30-1200 |

| Thickness | micron | 12-100 |

| Shrinkage | % | TD:1-50 MD: 1-5 |

| Shrink Temperature | ℃ | 90-150 |

| proportion | g/cm³ | 1.4 |

| Tensile Strength | MPA | TD:≥42 MD: ≥50 |

| Transverse elongation at break | % | TD:≥70

MD: ≥50 |

| Tear strength | KN/M | TD:≥60 MD: ≥45 |

Product Applications

Most of the available drinks use PVC labels, such as black tea, green tea and mineral water bottles.The surface is very durable and not easy to scratch and damage. As PVC label film has good flexibility, it can be bent and folded without breaking, suitable to be attached to irregular shapes. It is very popular in many industries.

Product Advantages

1. High Print Quality

Excellent surface finish for high-resolution printing, ensuring vibrant and detailed label designs.

2. Durability and Scratch Resistance

Resistant to wear, tear, and environmental factors, ensuring labels remain intact and readable.

3. Flexibility and Conformability

Can be easily bent and molded to fit irregularly shaped containers without cracking or peeling.

4. Wide Application Range

Suitable for various industries, including beverages, cosmetics, pharmaceuticals, and consumer goods.

5. Customizable Sizes and Thicknesses

Available in different widths (30-1200 mm) and thicknesses (12-100 microns) to meet specific packaging needs.

6. Enhanced Product Presentation

Improves the overall appearance of products, making them more attractive to consumers.

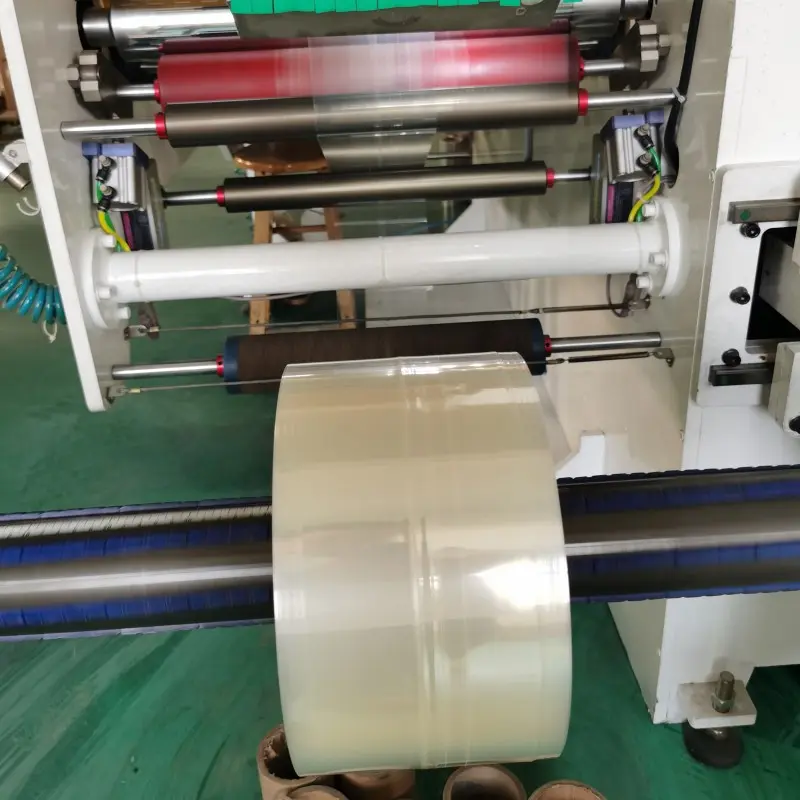

7. Easy Application

Simple to apply using standard shrink labeling equipment, ensuring efficient production processes.

8. Moisture and Chemical Resistance

Protects printed labels from moisture and chemical exposure, maintaining label integrity.

9. Versatile Shrink Properties

Adjustable shrinkage rates (TD: 1-50%, MD: 1-5%) to fit various container sizes and shapes.