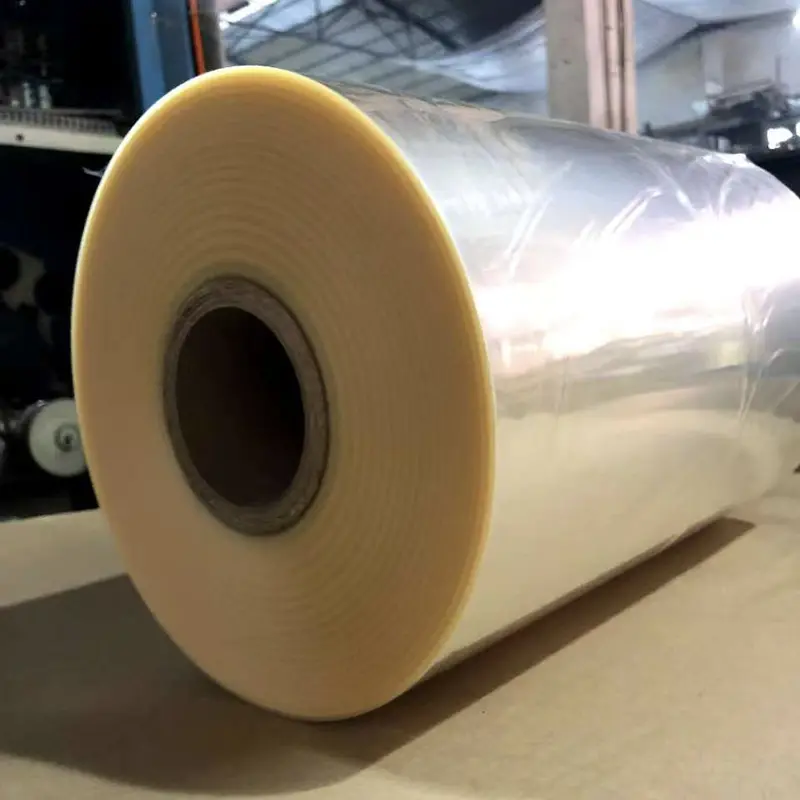

POF Shrink Film For The Automotive Packaging Machine Or Handmade Packaging

Product parameter

| TEST ITEM | UNIT | ASTM TEXT | TYPICAL VALUES | ||||

| GAUGE | 12um | 15um | 19um | 25um | 30um | ||

| TENSILE | |||||||

| Tensile Strength (MD) | N/mm² | D882 | 130 | 125 | 120 | 110 | 105 |

| Tensile Strength(TD) | 125 | 120 | 115 | 105 | 100 | ||

| Elongation(MD) | % | 110 | 110 | 115 | 120 | 120 | |

| Elongation(TD) | 105 | 105 | 110 | 115 | 115 | ||

| TEAR | |||||||

| MD at 400gm | gf | D1922 | 10.0 | 13.5 | 16.5 | 23.0 | 27.5 |

| TD at 400gm | 9.5 | 12.5 | 16.0 | 22.5 | 26.5 | ||

| SEAL STRENGT | |||||||

| MD\Hot Wire Seal | N/mm | F88 | 0.75 | 0.91 | 1.08 | 1.25 | 1.45 |

| TD\Hot Wire Seal | 0.78 | 0.95 | 1.10 | 1.30 | 1.55 | ||

| COF(Film To Film) | |||||||

| Static Dynamic | D1894 | 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |

| 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |||

| OPTICS | |||||||

| Haze | % | D1003 | 2.1 | 2.5 | 3.1 | 3.6 | 4.5 |

| Clarity | D1746 | 98.5 | 98.0 | 97.0 | 95.0 | 92.0 | |

| Gloss@45D | D2457 | 88.0 | 87.0 | 84.0 | 82.0 | 81.0 | |

| SHRINKAGE PROPERTIES | TD | MD | |||||

| Free Shrinkage | 100℃ | % | D2732 | 23 | 32 | ||

| 110℃ | 37 | 45 | |||||

| 120℃ | 59 | 64 | |||||

| 130℃ | 67 | 68 | |||||

| Shrink Tension | 100℃ | Mpa | D2838 | 1.85 | 2.65 | ||

| 110℃ | 2.65 | 3.50 | |||||

| 120℃ | 2.85 | 3.65 | |||||

| 130℃ | 2.65 | 3.20 | |||||

The above evaluation data are for reference only.

Product Applications

Standard POF is Especially suitable for use as a folding film, because of its good opening, of course, can also be used for monolithic film. The adaptability to the packaging machine is very good, can adapt to most of the automatic, semi-automatic packaging machinery requirements, is a very widely used and affordable products. Conventional thickness: 12um, 15um, 19um, 25um, 30um.

POF is mainly used for packaging rules and irregular shape products, because of its non-toxic environmental protection, high transparency, high shrinkage, good heat sealing performance, high gloss, strong toughness, tear resistance, heat shrinkage uniform and suitable for automatic high-speed packaging, widely used in automotive supplies, plastic products, stationery, books, electronic, circuit board, MP3, VCD, crafts, frame, wood products, toys, pesticides, etc, daily necessities, food, cosmetics, canned beverage, dairy products, medicine, tape and video products.

Product Advantages

1. Versatility and Cost-Effectiveness

Suitable for a wide range of packaging applications.

Economical solution that reduces material and transportation costs.

2. Enhanced Performance

Excellent shrink properties ensure a tight and secure fit around products.

Superior protection against physical damage, moisture, and contamination.

3. Aesthetic Appeal

High transparency and gloss enhance the visual appeal of packaged goods.

Attractive appearance that boosts product visibility on store shelves.

description2