POF, PVC and PE Shrink Film Packaging

Owing to its multipurpose character, shrink film provides requisite packaging functionality with properties aiding the product's protection and ability to maintain integrity. Among various shrink film types, POF (Polyolefin), PVC (Polyvinyl Chloride), and PE (Polyethylene) shrink films are the most commonly adopted for their diverse beneficial properties for niche applications.

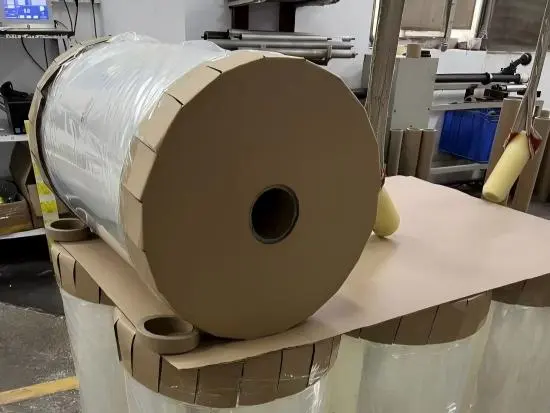

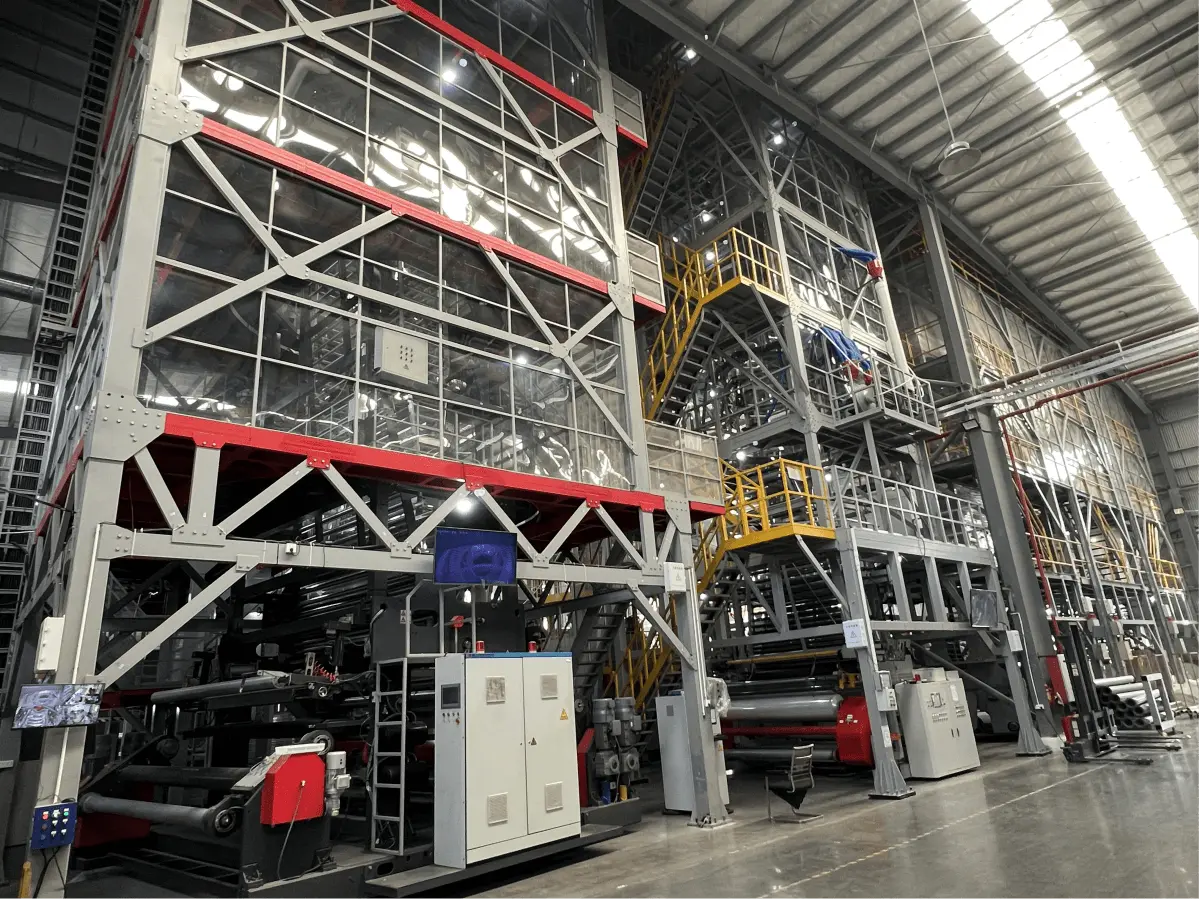

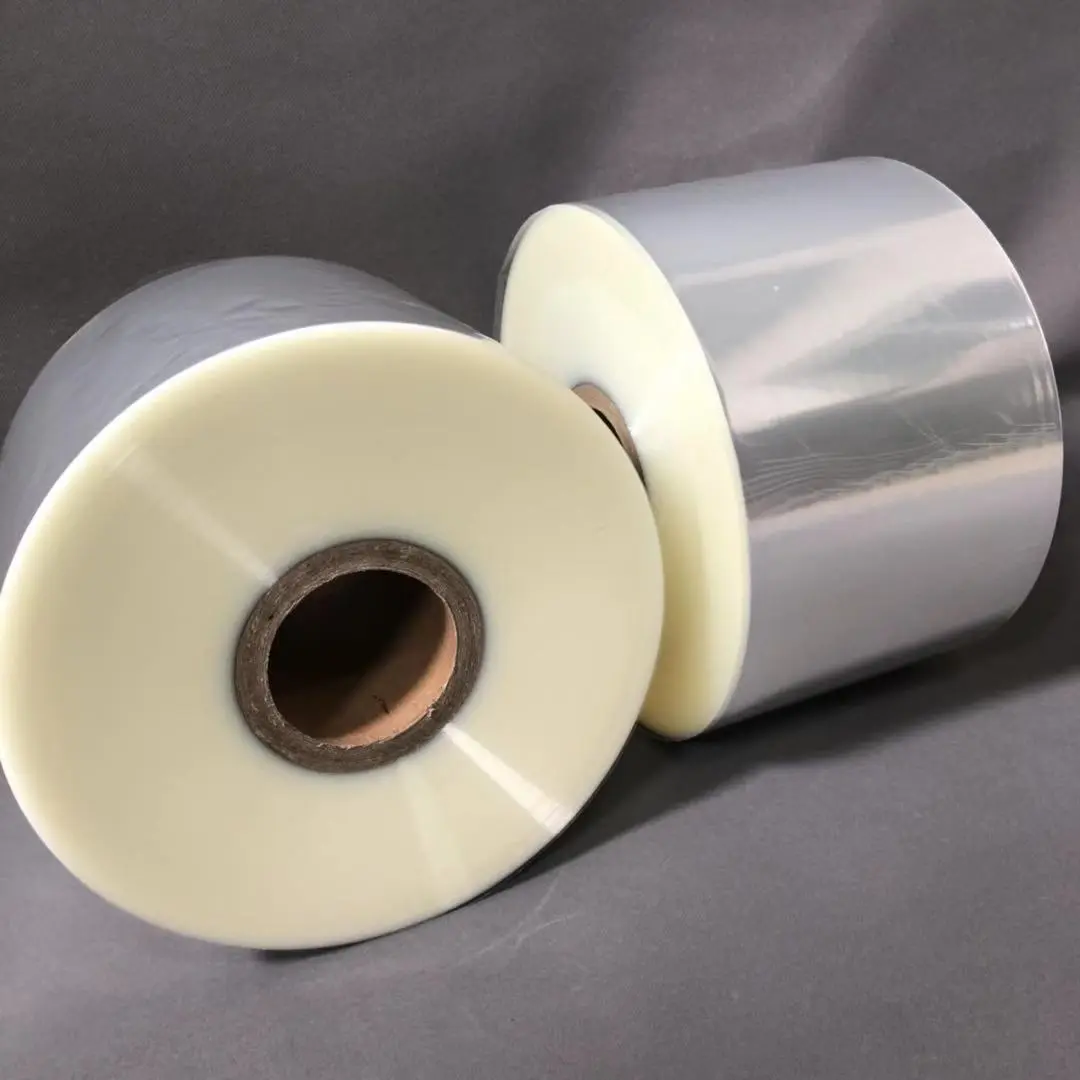

Polyolefin (POF) shrink film has become the film of choice due to its clarity and strength. Pof Shrink Film is used for packaging various consumer goods, such as toys, books, and electronics, thanks to its gloss giving an aesthetic touch to the products; and that it has dust-free handling properties. It is a multilayer co-extruded film with fantastic puncture properties, designed for irregular-shaped items. Puncture-resistant characteristics make POF shrink film well suited for food and non-food products in direct contact with food, according to food safety specifications. The high thermal performance across a wide range of temperatures gives the end-user even more reason to rejoice with the application in packaging and presentation. You can know more byhttps://www.tcn-materials.com/ and discuss by email sales@tcnmaterials.com.

Polyvinyl Chloride (PVC) shrink film is a classic yet very much loved kind of material in the packaging circle, whereby lots of shrink properties and economy are applied. Heavy and durable seals are a typical highlight of PVC shrink films, rendering protection against tampering and environmental contaminants and therefore being used in pharmaceuticals and cosmetics or other sensitive products. With high functionality, however, environmental practices have started to frown upon PVC shrink films because of their content of chlorine and their relatively low recyclability. Nevertheless, current research is being geared toward the sustainability of Pvc Films through new formulations and better recycling practices. You can know more byhttps://www.tcn-materials.com/ and discuss by email sales@tcnmaterials.com.

Polyethylene (PE) shrink film is appreciated for its high strength and tear resistance and is considered the preferred material for bundling applications and for pallet stabilization in industrial usage. PE shrink films can be classified broadly in three types: low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). Each type offers individualized benefits, such as flexibility, tensile strength, and better clarity. PE shrink films are considered best for applications for heavy-duty performances, i.e., in transportation and storage of bulk goods. The water resistance property of PE shrink films stays in favor of moisture protection from the harsh environmental factors in which products can be manufactured, stored, or applied. You can know more by https://www.tcn-materials.com/ and discuss by email sales@tcnmaterials.com.

These three kinds of shrink films-Pof, Pvc, and Pe-shrink film will, therefore, depend on the final requisite from the packaging application. For food safety, POF wins predominantly for transparency, whereas PVC is praised for tamper and seal strength, and in heavy-duty service, PE is the moisture rejection champion. These shrink films continue to advance themselves towards meeting the sustainability requirements posed by changes in the packaging industry and modern technologies, thus ever being present to shield products and package them.