How POP/PVC Shrink Film Slitting Machines Are Changing the Packaging Game

You know, the packaging world keeps on evolving, and tools like the POP/Pvc Shrink Film slitting machine are really making a difference when it comes to boosting efficiency, quality, and cutting costs. These newer machines are built to handle the growing need for versatile packaging options, which are super important for industries like food and beverages, pharma, and everyday consumer goods.

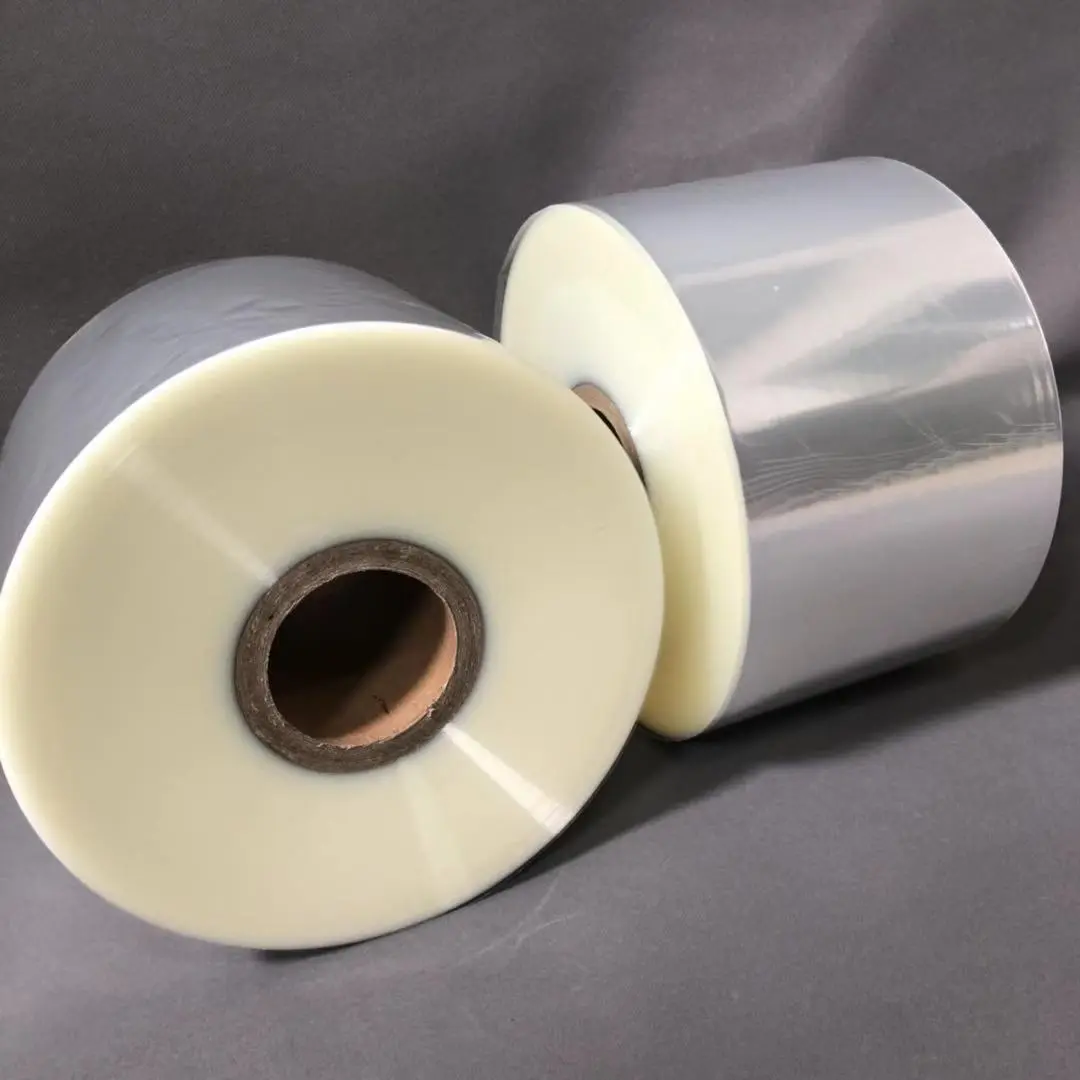

Shrink films—whether Polyolefin (POP) or Polyvinyl Chloride (PVC)—are everywhere because they work so well. They protect products from dirt and germs, make items look more appealing on shelves with tamper-evident seals, and can be shaped to fit all kinds of products. But here’s the thing—getting the film cut into just the right size was a pain in the neck for a long time. That’s where modern slitting machines come in to save the day.

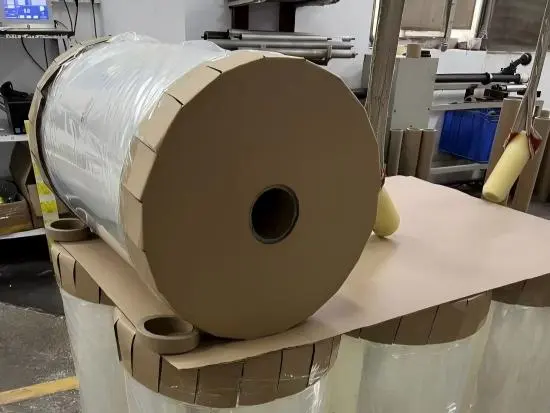

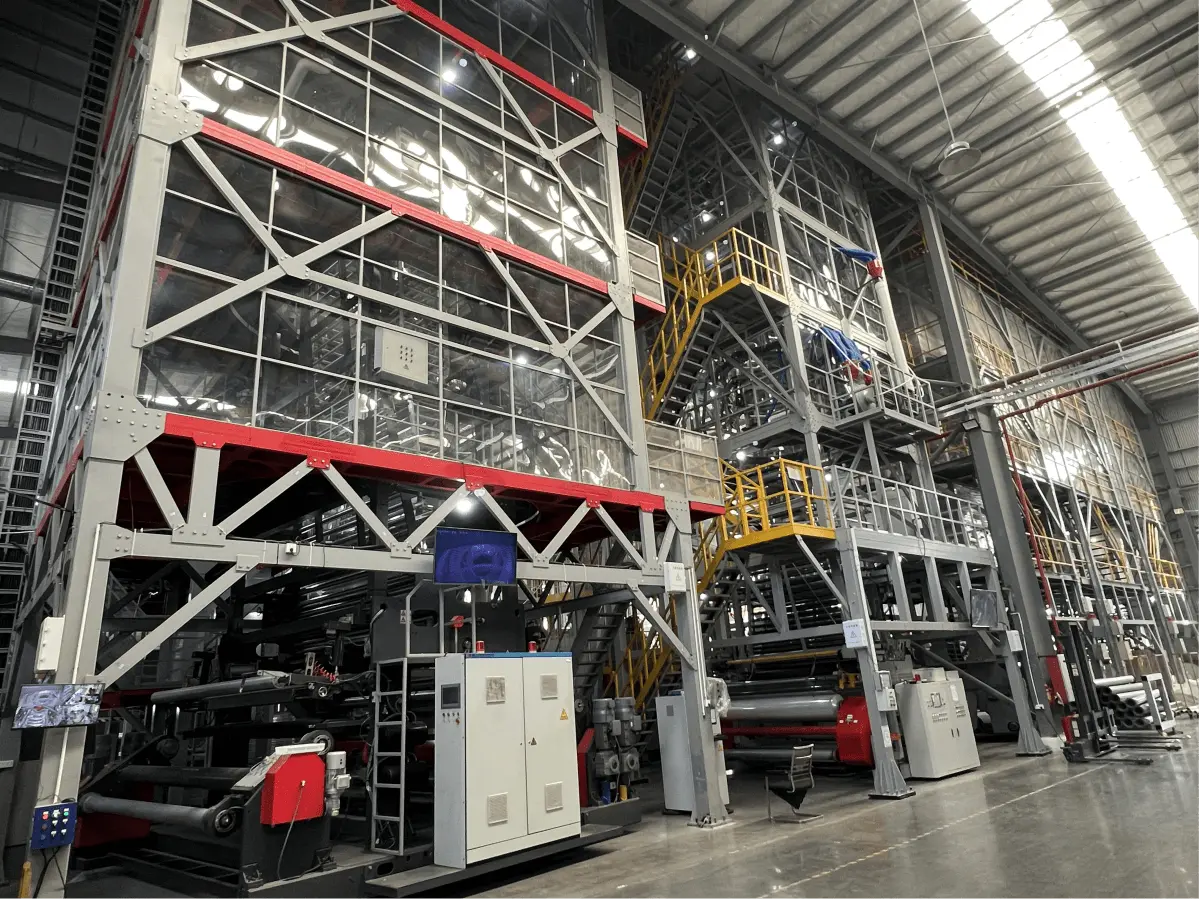

A POP/PVC shrink film slitting machine is basically designed to take these thick rolls of film and slice them into super thin, precise strips—almost like magic. The cool part? They’re fast, accurate, and pretty flexible. Thanks to the latest tech and smart software controls, these machines consistently make perfect cuts, squeezing out every bit of material and cutting down waste—something that’s a big deal now with raw material prices going up.

Operators don’t have to be tech wizards to run these machines. They usually come with touch screens and auto settings that make managing film tension and cut widths pretty straightforward. This means workflow gets smoother, and mistakes happen less often, leading to a better final product. Plus, these machines are tough enough to handle both POP and Pvc Films, even when running on a large scale—so whether it’s a small batch or mass production, they’ve got it covered.

Another thing I like is how energy-efficient these newer models are. With smart motors and eco-friendly practices, they help slash energy bills and make the whole process greener—something companies are really focusing on these days.

And the financial benefits? Well, manufacturers using these machines usually see faster turnaround times, lower labor costs, and higher output rates. The initial investment? It’s often balanced out pretty quickly thanks to savings on materials and the boost in quality. Plus, since markets can change pretty fast, having a machine that’s adaptable is huge—it keeps companies flexible and ready to respond.

All in all, bringing in POP/PVC shrink film slitting machines really is a game-changer for packaging. They combine tech precision, efficiency, and eco-friendliness, helping businesses improve everything from production speed to product quality. As the industry keeps pushing toward more innovative stuff, these machines are quickly becoming a must-have for modern manufacturing setups.

Zhongshan Tiancheng New Materials Co., Ltd professionally match you the good slitting machine for your films. We can offer the good quality shrink film slitting machines with competitive price. We are sure to offer you the valuable products. You can get more information by https://www.tcn-materials.com. and contact by email sales@tcnmaterials.com or whatsapp 86-13420303721.