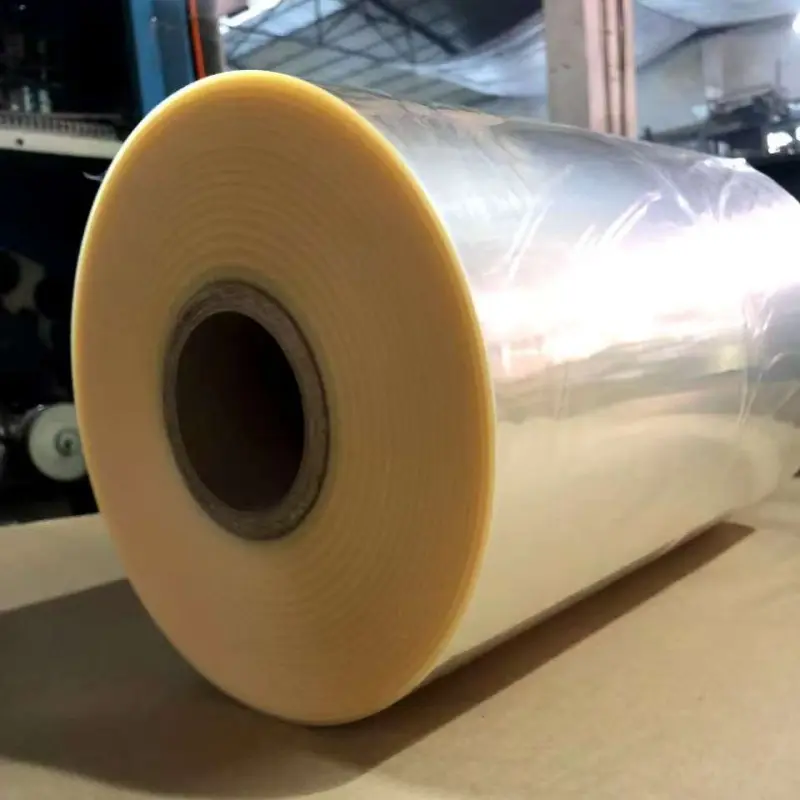

High Quality POF Center-Fold For Packaging Machine

Product parameter

| TEST ITEM | UNIT | ASTM TEXT | TYPICAL VALUES | ||||

| GAUGE | 12um | 15um | 19um | 25um | 30um | ||

| TENSILE | |||||||

| Tensile Strength (MD) | N/mm² | D882 | 130 | 125 | 120 | 110 | 105 |

| Tensile Strength(TD) | 125 | 120 | 115 | 105 | 100 | ||

| Elongation(MD) | % | 110 | 110 | 115 | 120 | 120 | |

| Elongation(TD) | 105 | 105 | 110 | 115 | 115 | ||

| TEAR | |||||||

| MD at 400gm | gf | D1922 | 10.0 | 13.5 | 16.5 | 23.0 | 27.5 |

| TD at 400gm | 9.5 | 12.5 | 16.0 | 22.5 | 26.5 | ||

| SEAL STRENGT | |||||||

| MD\Hot Wire Seal | F88 | 0.95 | 1.11 | 1.28 | 1.45 | 1.65 | |

| TD\Hot Wire Seal | 0.98 | 1.15 | 1.30 | 1.50 | 1.75 | ||

| COF(Film To Film) | |||||||

| Static Dynamic | D1894 | 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |

| 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |||

| OPTICS | |||||||

| Haze | % | D1003 | 2.1 | 2.5 | 3.1 | 3.6 | 4.5 |

| Clarity | D1746 | 98.5 | 98.0 | 97.0 | 95.0 | 92.0 | |

| Gloss@45D | D2457 | 88.0 | 87.0 | 84.0 | 82.0 | 81.0 | |

| SHRINKAGE PROPERTIES | TD | MD | |||||

| Free Shrinkage | 100℃ | % | D2732 | 38 | 43 | ||

| 110℃ | 52 | 55 | |||||

| 120℃ | 64 | 66 | |||||

| 130℃ | 71 | 73 | |||||

| Shrink Tension | 100℃ | Mpa | D2838 | 1.85 | 2.65 | ||

| 110℃ | 2.65 | 3.50 | |||||

| 120℃ | 2.85 | 3.65 | |||||

| 130℃ | 2.65 | 3.20 | |||||

The above evaluation data are for reference only.

Product Applications

Low temperature POF can be used for packaging the products of all kinds of industries. In addition, Low temperature POF also has the advantages of wide shrinkage temperature range, good thermal sealing performance and low shrinkage force. Among the non-cross-linked POF thermal shrink film varieties, Low temperature POF is the best shrink packaging effect. The Low temperature POF is suitable on any packing machine.

Product Advantages

1. Wide Shrink Temperature Range

Suitable for various packaging machines, ensuring consistent performance across different operating conditions.

2. Excellent Thermal Sealing Performance

Provides strong and reliable seals, reducing the risk of package failure and ensuring product protection.

3. High Clarity and Gloss

Enhances product visibility and presentation, making packaged goods more attractive on shelves.

3. Customizable Thickness and Width

Available in multiple thickness options (12um to 30um) to meet specific packaging requirements.

4. Easy Handling and Processing

Designed for seamless integration with automated packaging machines, improving efficiency and reducing labor costs.

5. Enhanced Packaging Aesthetics

Low haze and high gloss improve the overall appearance of the package, adding value to the product.